Centerfold VS Single-Wound Shrink Film: Which Is Right For You?

So, you have been tasked with purchasing shrink film for your company's packaging needs. You went to Google, searched for shrink film, and you found two common types of this material. Single-wound shrink film and centerfold shrink film.

Now what? Which type of shrink film is right for your products? Is one or the other more appropriate for your packaging line? How do you identify which type of shrink film is right for you?

You do this by understanding your desired package appearance, your machine's capabilities, and your production requirements, guiding you to the appropriate choice.

Industrial Packaging has been selling shrink films for decades while providing our customers with quality information to make proper buying decisions. When it comes to your shrink film requirements, you will find the resources you need to choose the right film here.

This article will help you figure out if single-wound or centerfold shrink film is right for you.

What Is Single-Wound Shrink Film?

Single-wound shrink films come on a flat sheet which is wrapped onto a core. Single-wound films are also known as single-layer or flat films. They are commonly used for the packaging of various types of consumer products.

Our single-wound films are available from 35 gauge to 150 gauge. The gauge of the film will determine the footage of the roll. Film lengths range from 3,500 to 15,000 feet. We currently offer widths of single-wound film ranging from 6 inches to 58 inches.

When packaging products with a lap seal machine, the seal is on the leading edge, the trailing edge, and the bottom of the package. When packaging products on an L-bar sealer or a side sealer, the three seals appear on the leading edge, the trailing edge, and one of the sides. Generally speaking, lap seal machines have an electric or static seal on the bottom. This is to hold the overlapping layers of the film together.

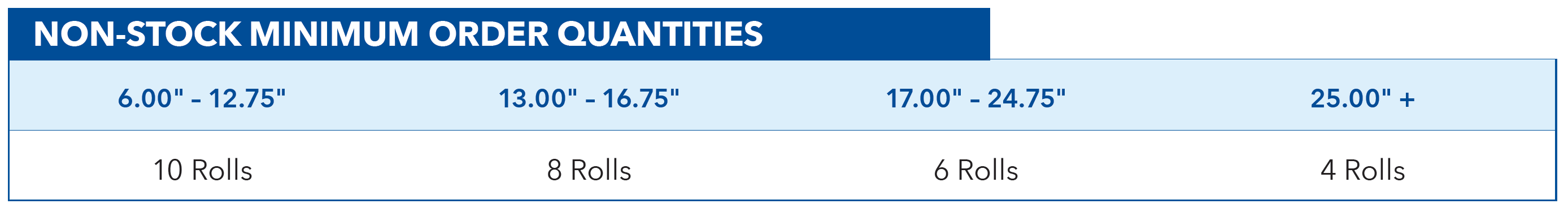

The following single-wound films have the noted minimum order quantities and have an approximately 4-week lead time.

What Is Centerfold Shrink Film?

Centerfold shrink film is folded lengthwise in half. It is then rolled onto a core to form a roll. A 20-inch-wide centerfold roll would unfold into 40-inch width.

Our centerfold films are available from 35 gauge to 150 gauge. The gauge of the film will determine the footage of the roll. Film lengths range from 1,750 to 8,750 feet. We currently offer widths of centerfold film ranging from 6 inches to 58 inches.

Centerfold shrink film is used for various applications ranging from tabletop shrink machinery to L-bar sealers to side sealers.

When using centerfold shrink film, the sealer will seal the front, the back, and the side of the film before being sent into the heat tunnel.

Depending on the distributor's inventory, you can buy individual rolls or pallet load quantities of centerfold shrink film.

Need Help Choosing The Right Shrink Film?

Applications For Single-Wound VS Centerfold Shrink Film

When packaging your products on an L-bar sealer or side sealer, the seal is visible on three sides. With a lap seal machine, the seal appears on two sides with an overlapped seal on the bottom.

Centerfold shrink film can run on various types of side or L-bar sealers. Single-wound films run on horizontal form, fill and seal machines (lap sealers), and side sealers with center-folders. The main difference here is the type of machinery that these films are commonly run on.

When it comes to the product packaging itself, the aesthetic of the package can be a concern based on where the seals are placed. Depending on how you want your packaging to look on the shelf, you will need to decide where you want your seals to show and choose the correct application.

Single-Wound Or Centerfold Shrink Film: Which One Is Right For Me?

When choosing between single-wound and centerfold shrink film, the decision is made based on the desired package appearance or the type of sealer you have. If you want a lap seal, you must buy single-wound film.

If you are comfortable with a three-sided seal, you can use centerfold or single-wound shrink film (if your sealer is equipped with a center-folder).

Advantages of Single-Wound Shrink Film:

- Longer rolls.

- Fewer roll changes and less downtime.

- Cradle packs are often available, resulting in less trash.

Disadvantages of Single-Wound Shrink Film:

- Single-wound rolls weigh twice as much as center-folded rolls.

- If you buy 24-inch center-folded film, you will have half the roll length and half the roll weight of a 48-inch single-wound roll of shrink film.

- Single-wound shrink film may require a hoist which will add an additional cost.

- If your using single-wound shrink film, the center-folder is an additional piece of equipment that would require maintenance and may fail.

- A center-folder requires accurate installation and set-up each time you put the roll on the machine. You need to make sure the film is folded evenly.

- Most distributors stock various widths of centerfold shrink film. Single-wound film is traditionally customer-specific and custom-made. Rarely does a distributor stock single wound film that has longer lead times. If a customer can buy centerfold film from a distributor's inventory, lead times may decrease by up to 4 weeks.

Reading the list above, one might wonder; why would anyone choose single-wound film if they can use centerfold film? The answer is, for long high-production runs, the savings in reduced changeovers is worth it.

More Resources For Sourcing Shrink Film

Would you like to learn more about shrink film to inform your buying decision? If so, you will want to check out our learning center. There, you can find tons of useful information about shrink film. This information will help you to purchase the right film for your needs.

Would you like a recommendation from a packaging professional? If you would, consider reaching out to one of our packaging experts. They will be able to help you choose the right film regardless of whether you buy from us or not.

About Nathan Dube

As the Digital Marketing Specialist at Industrial Packaging, I am honored to create content for such a phenomenal company and work with one of the greatest teams in the Packaging Industry. Whether creating a video, writing blog posts or generating other pieces of content and multimedia, I am always excited to help educate and inspire our prospects and clients to reach their highest potential in regards to their packaging processes and needs.