How To Replace Stretch Film And Strapping With One Material

Stretch film and strapping are often used in tandem for palletizing and securing heavy obscure loads. In such cases, pallets will often be secured with four or more bands of strapping and then wrapped with stretch film.

This tactic is an excellent way to ensure that heavy and oddly shaped loads are properly contained so they do not fall or go lopsided during transit and storage.

Many companies use stretch film and strapping in tandem for applications as described above. But, having to use these two materials can be pricey.

Pallets that are wrapped in both strapping and stretch film require extra material to ensure proper load containment. And this leads to the need for extra labor or automation to complete the process of applying these materials to your pallets of products.

In a world where everyone is looking for ways to cut costs, these processes are concerning as they are expensive to implement. This is especially true when the cost of packaging materials continues to rise regularly.

Many companies are looking for a way to eliminate extra packaging in an effort to reduce the cost of their product palletizing protocols.

Many businesses ask themselves, "wouldn't it be great if we could replace stretch film and strapping with a single packaging material?"

And, we must agree that it would be awesome if this could be done. If you could swap out two materials for one, you could save time, money, and labor by using only one type of packaging to palletize your products.

Well, we have good news for you.

Thanks to Alliance Plastics, there is now a single type of flexible packaging film called steelflex titanium stretch film that can replace the use of traditional stretch film and strapping for the types of applications mentioned above!

But, how is this film able to accomplish this? And, where can you purchase this material?

In this article, we will explain how you can use steelflex titanium stretch film to replace the use of traditional stretch film and strapping for palletizing heavy and obscure loads!

Stretch Film And Strapping For Wrapping Heavy Loads

When companies who produce very heavy products are ready to palletize, secure and contain their products for shipping and storage, they often turn to stretch film or strapping to accomplish these goals.

And when the products are super heavy, many companies will combine stretch film with strapping to palletize their products correctly.

This prevents ultra heavy loads from falling down during transportation and storage. And as collapsing loads can be a safety hazard, many companies are willing to pay a premium to use both materials together.

They are often willing to do this even though it is much more costly than using one material for this process because it ensures their loads arrive at their customers intact and adequately contained.

Want to learn more about stretch film?

How Is Stretch Film And Strapping Used For Securing Heavy Loads?

When a company has ultra-heavy pallets or products to secure and contain for transport and storage, they will often use stretch film in tandem with strapping to ensure that the loads stay safely secured.

This is done by applying both materials to a pallet of products. When securing pallets like this, most people start by applying strapping to the products on the pallet.

Most of the time, this will be polyester or polypropylene strapping material. Generally speaking, four straps of material will be applied to the pallet using a hand strapping tool called a tensioner.

The tensioner is used to tighten the strapping tightly around the products on the pallet. Most of the time, there will be two straps applied lengthwise and two straps applied crosswise.

Next, the pallet will be wrapped with stretch film. This is either done by hand while simply holding the roll of film or using a stretch wrap dispenser while walking around the pallet in a circle until the pallet is fully wrapped in stretch film.

This process can partially or fully automated with an automated stretch wrapper. As noted, the application of these two packaging materials requires extra time and labor to apply each material.

But what if you could replace stretch film and strapping with a single flexible packaging film? This could save you time, money, and labor by reducing the number of materials needed and the work and time it takes to apply the film.

And that is where steelflex titanium stretch film comes in.

Steelflex Titanium Stretch Film To Replace Traditional Stretch Film And Strapping For Ultra Heavy Loads

Until now, no stretch film on the market could replace traditional stretch film and strapping for ultra-heavy and oddly shaped loads.

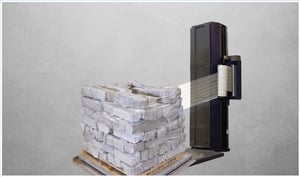

Ultra-heavy products with sharp edges such as cinder blocks, steel, and industrial equipment would often tear even the strongest traditional stretch films on the market.

In these situations, many companies would augment excessive stretch wrap on these products with strapping to ensure that the loads would not go lopsided or collapse from the products tearing the stretch film.

But, today, there is an alternative film that can replace traditional stretch film and strapping for these loads. Steelflex titanium stretch film can contain these loads without the need to add strapping material.

Thanks to bands of Alliance Plastics patented power bands which run in streams throughout steelflex titanium stretch film; you can wrap these ultra-heavy loads with this film and this film alone.

By switching from the use of traditional stretch film and strapping for heavy and obscure loads to steelflex titanium stretch film, you will reduce the cost, labor, and materials needed to wrap your loads.

This will result in notable cost savings and will allow you to secure your pallets faster and with less labor.

By replacing the use of four straps plus stretch wrap with reinforced titanium stretch film, you will accomplish two incredible feats. First, you cut the cost of using four plastic straps. This reduces the cost of pallet securing materials by about 40-50%.

By removing the time to apply four straps manually, you can save about 12 minutes per pallet.

At twenty dollars per hour for labor, this translates to $4.00 per pallet in labor savings. Added together, this is about $6 per pallet load of savings.

So, with only 166,666 loads, you can save one million dollars! In essence, if traditional stretch film and strapping had a baby, it would be steelflex titanium stretch film!

Where Can You Buy Steelflex Titanium Stretch Film?

After reading this article, you are probably very interested in learning more about steelflex titanium stretch film and are considering purchasing this material.

If that is the case, you will want to consider speaking with one of our in-house packaging experts. They can answer any questions you have about this type of stretch film.

They will also be able to provide you with pricing and help you to choose the proper gauge and formulation of steelflex titanium stretch film for your heavy load containing and securing applications.

About Nathan Dube

As the Digital Marketing Specialist at Industrial Packaging, I am honored to create content for such a phenomenal company and work with one of the greatest teams in the Packaging Industry. Whether creating a video, writing blog posts or generating other pieces of content and multimedia, I am always excited to help educate and inspire our prospects and clients to reach their highest potential in regards to their packaging processes and needs.