How To Determine The Yield Of Your Shrink Film

Determining the yield of your shrink film can help you optimize your film choices to help you run an efficient packaging line on which you will be able to squeeze every last ounce of value from.

However, if you are reading this article, you are probably trying to figure out how to determine the yield of your shrink film. With that being said, you probably have a few questions about yield including:

When do you need to determine the yield? You will likely have to be able to show the metric of yield in reports regarding waste reduction or other financial KPIs which will be effected by yield. Being able to show this data quickly will help you to shorten and simplify the buying process.

Is it commonly difficult to calculate yield? If you are not a fan of doing math, calculating your yield can be frustrating. We will help you to do it with ease.

Is calculating yield a common metric to calculate? Many companies over look this valuable metric, but others do not. Understanding your yield will help you to make better purchasing decisions and help you to reduce costs and waste.

Does choosing the wrong film yield lead to wasted dollars? Yes! This is not something you want to get wrong.

With the correct yield in hand, you will be able to choose the right film for your packaging needs and also choose the film which you will be able to get the most value out of.

Industrial Packaging has been selling shrink film for generations. We are going to help you understand how to determine the yield of each type of film so that you can choose the right film for your unique packaging applications.

How To Determine The Yield Of Your Film

To calculate your shrink film yield, you will need to understand a few metrics from a mathematical equation. Below, we will explain a couple of required elements for adequately calculating the appropriate yield for your choice of film.

What Is Shrink Film Gauge?

When people are discussing the gauge of shrink film, what they are essentially talking about is the thickness of the film. As this is important to remember, please keep in mind that gauge is a measurement of thickness.

The larger the number of your shrink film's gauge, the higher the thickness your shrink film will be. This thickness will be measured using the terms mil or gauge.

When we talk about mil thickness, what we are discussing is the standardized industry measurement. In the packaging industry, the gauge is simply a common nickname used by packaging experts to describe the thickness of a film.

A "mil" just so happens to be precisely one-thousandth of an inch (represented as a decimal, this number is .001). As a point of interest, it should be noted that within our industry, when folks are speaking about premium formulations of shrink film, it is common practice to use the term "gauge" rather than a mil.

For example, someone may say, "Hey, get me a pallet of 75 gauge shrink film". Now, when people are discussing polyethylene shrink film, they are going to speak in terms of mils, e.g., one mill, two mill, three mil and so on.

If you are looking to convert mills to gauge, you are going to have to multiply the number of mills x 100. This little calculation is known as the "conversion factor".

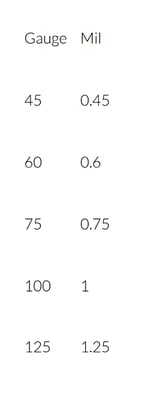

To illustrate this, let's take a look at the following information: 1 mil x 100 would equal 100 gauge. Below, you will find a handy chart that will detail thickness conversions to help make this process easier for you:

*Note the lesser the gauge, the thinner the shrink film will be. This is opposed to other material calculations, such as when dealing with fine jewelry. A 14 gauge is smaller than a 0 gauge. A 75 gauge shrink film is going to be thinner than a 100 gauge film.

Need Help Choosing The Right Shrink Film?

How To Calculate Shrink Film Width

When you are trying to calculate the width of your shrink film, there are several dynamics which you will have to take a look at to calculate your shrink film width accurately. These include:

- Your Package's Height

- Your Package's Width

(AKA: Cross Direction or CD). This pertains to the measurement that runs on the opposite side of the direction the product is traveling on your packaging line - Your Package's Shape

Is it symmetrical, like a box, or odd-shaped, like a football? - The Type Of Sealer You Are Using

To determine the correct film width, you need to understand the dynamics mentioned above. When using a horizontal F/F/S system that uses a forming plow for fixed films, film sizing is based on the forming plow dimensions rather than the dimensions of the package itself.

When the dimensions of the forming plow are known, the width of the shrink film is a function based on the plows dimensions plus an overlap seal metric. When you are trying to size the plow, you need to make the inside dimensions as small as possible to accept the product. This is to make for wiggle room regarding the size of your product.

How To Determine The Yield Of Your Shrink Film

When it comes to the different types of shrink film, you are generally dealing with three main formulations of shrink film. The three most common formulations of shrink film are polyvinyl chloride (PVC), polyethylene (PE), and polyolefin (POF).

While each type of film is made for specific types of different applications, the math required to calculate the yield is the same for all three types of shrink film mentioned above.

There are 30,000 square inches in 1 pound of 1 mil polyethylene shrink film. Each roll weighs a different amount based on the square inches per pound per mill thickness. For example, let us say that you have a 14" x 125 gauge x 7,500' roll, which weighs 52.5 pounds, and a typical pallet may have 20-24 rolls. The yield would be 22,500 sq" per pound.

Of course, you don't have to do all this math yourself if you would prefer not. When trying to calculate the yield for your films, you can always reach out to your packaging vendor and ask your rep to do this work for you.

If you do not currently have a packaging materials vendor, it would be wise to compare a few different companies and choose the one that best fits your needs.

If you are not sure where to start, please reach out to one of our packaging experts. They will be able to help you calculate your shrink film yields and help you to choose the right packaging materials vendor, regardless of whether or not that is us.

About Nathan Dube

As the Digital Marketing Specialist at Industrial Packaging, I am honored to create content for such a phenomenal company and work with one of the greatest teams in the Packaging Industry. Whether creating a video, writing blog posts or generating other pieces of content and multimedia, I am always excited to help educate and inspire our prospects and clients to reach their highest potential in regards to their packaging processes and needs.