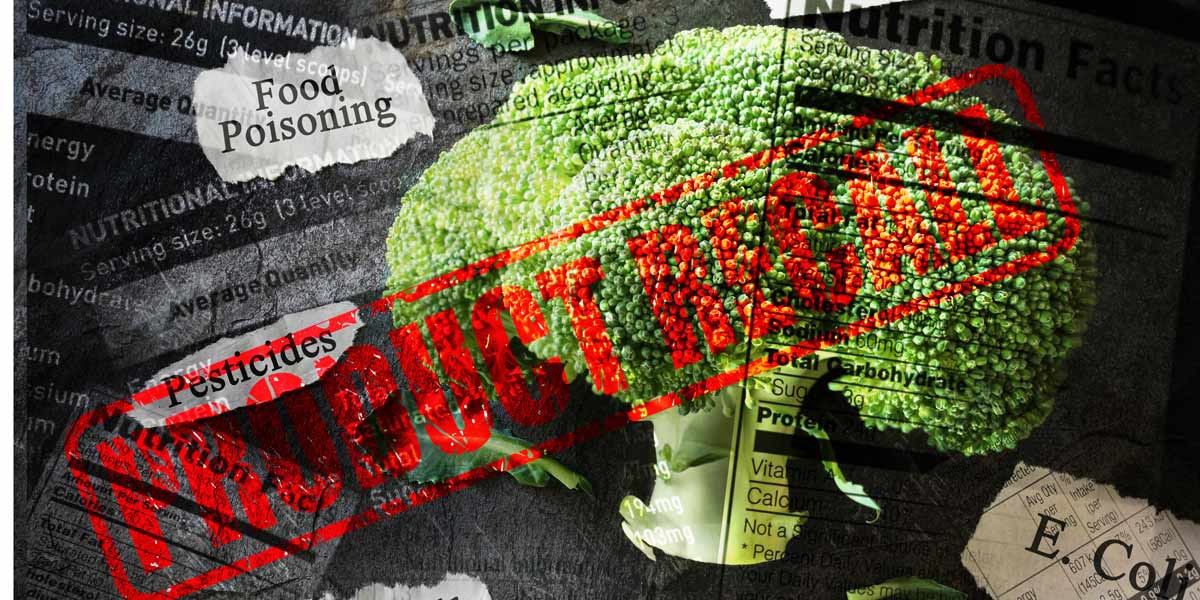

5 Common Food Labeling Mistakes to Avoid

Packaging Materials | The Business of Packaging | Investment | Packaging Design | Food Packaging

Food labeling is a highly scrutinized, crucial part of food product manufacturing. However, it also can be an easily rushed and/or overlooked part of bringing a product to market. It's easy to make simple mistakes no matter how large or small your operation may be. It's also easy to steer clear of any issues when you are well-prepared with a plan and process and when you are working with a supplier that will assist you along the way to launch.

There are quite a few common mistakes that happen with labeling food so I've compiled a list of five important ones to avoid:

1. The Label is Illegible or Portions of the Label are Illegible

According to the USDA's Food Safety and Inspection Service (FSIS), one of the ten most common food labeling mistakes is illegible labels, and it's one of the basic legal requirements.

Having the approval of the FSIS is a requirement if your products are manufactured for household consumers and/or if they include claims, guarantees, or foreign language. Your food products won't make too much movement in the marketplace if the labeling is difficult to read; let alone if the words are completely un-readable. It can be even more disastrous if the labels are missing important information and your product makes it to the shelf; leading to recalls or even worse, causing harm to a consumer.

When you're a high volume, multi-product food manufacturer these legibility mistakes tend to be more common. Why? It can be challenging to maintain order when you are managing hundreds of labels for different products, SKU's, and retailers. It's important to have the right labeling machinery and software in place. Work with your packaging/labeling supplier to find the machinery and software that can handle the volume that your retailers and consumers demand while reducing or eliminating the opportunity for legibility mistakes to happen.

2. Single Ingredients are not Listed by Common Name

How you list the ingredients in your foods is another very common mistake in labeling foods. Unless you intend to violate FDA regulations, be sure to take no shortcuts when listing each and every item (and their sub-ingredients) used in the food products you produce.

A common name is required for every ingredient so you should avoid using abbreviations or trade names on your nutrition panels. If you are using oil in your recipes, be sure to list the specific type of oil used; i.e., extra virgin olive oil. Your label will not pass the approval process of the FSIS if you choose to opt for simply 'oil' or 'EVOO'.

3. Nutrition Fact Problems

If you want to have a successful product that isn't a fad food and you want your brand to grow and last in the marketplace, there are two things you must do. First, you've got to be honest. Second, you've got to be sure of the facts you place on your nutrition labels.

Some items on your nutrition table may seem obvious but are often overlooked because of that very thought. Be sure to check, and double check your format. Check your serving size and servings per container, be sure you're rounding the values used properly, and be sure your reference amounts are accurate.

A publicized failure to provide correct nutritional facts does not bode well for brand loyalty, and it can have severe long-term repercussions. The popular UK supermarket brand, Tesco, faced a huge scandal back in 2010 when the Food Safety Authority of Ireland (FSIA) found that horse meat accounted for 29% of the beef content in 10 tested burgers that they tested!

The brand failed a PR recovery when they created an ad campaign that claimed the whole beef industry was doing it, too, as if that made their foul-up any better. The ad was banned by an ad regulator and in the end, Tesco's value dropped by more than $430 million.

Make sure you are not misleading in the ingredients labeling you place on your food products. The FDA is watching in the US, too. They stopped an overseas food importer from shipping pomegranate concentrates into the United states from Turkey and Iran after the juices were found to contain other unlisted ingredients.

4. Font too Hard to Read

It's important to test your food labeling design for readability. Follow any minimum requirements that the FDA publishes. Make sure you aren't overdoing the text on your labels with busy or small fonts. The messages, facts, and pertinent information about your food needs to be easy to read!

Remind yourself to check the style, size, and the contrast in color for readability when reviewing your font selection. This can build trust in the consumer looking for information on your packaging. It should go with out saying that your nutritional information is clear and simple to understand, too. The clearer you are about the product you are providing the consumer, the more they can feel confident in their purchase.

5. Basic Legal Requirements

Not following the basic legal requirements for food labeling is another common miss. Don't forget to include your statement of identity, country of origin name and place of business, net contents, ingredient statement, statement/warning on allergens, and last but not least, your nutrition facts panel.

It's important to keep the fine details for your food label at the top of your mind when preparing your product for the marketplace. From the type of labeling you choose to the rules that are often missed, you can make or break your product before it hits the marketplace with an unplanned and careless labeling and label management process. Try creating a checklist for your labeling design and internal approval process to make managing your food labels successful and easy.

If you want to get an understanding of how the packaging materials you select can impact your labeling options, get your free copy of The Ultimate Guide to Protective Packaging here!

About David Roberge

I am grateful to be part of the outstanding Industrial Packaging team. I am able to hang out with some of the most knowledgeable folks in the packaging industry. I feel even luckier that I am able to share that knowledge with you. I love learning, hiking, and growing people and teams both personally and professionally, and helping companies grow better.