When it comes to buying packaging machinery there are many variables involved. From researching machinery makes, models, and brands to choosing a vendor for service, supply, and preventative maintenance. Buying packaging machinery is a big investment for your business.

When considering the purchase of new packaging machinery, you will want to take the time to do your homework and invest due diligence into the process. If you want to know what types of machinery are available, the materials they run, their proper and safe operating procedures, and how to keep them running at peak performance, this guide will provide you with all the information you are looking for and then some.

Begin reading the full guide below, or fill out the form for a downloadable PDF version that you can reference later!

When it comes to preparing to invest in new packaging machinery, it is always wise to start by educating yourself on the top ten KPIs (or Key Performance Indicators) of your packaging line. Starting with a solid understanding of safety protocols and best practices is a wise place to begin this journey. Before we get started on why safety is the first KPI you should measure and ways to implement it, here are the top 10 packaging line KPIs:

At the start of your research into purchasing new equipment, the safety concerns surrounding packaging machinery are paramount to this process. Reaching out to a local vendor and requesting information about safety standards for the different types of machinery you will be buying is highly suggested.

A risk assessment is a necessary piece of documentation to ensure the safety of your employees. The goal of a risk assessment is to realize hazards, assess and reduce risk and provide documentation that validates the results of said assessment.

By conducting a risk assessment, you will help to ensure that your packaging line is run at the optimum levels of safety and that your employees are working with the lowest possible risk to their well-being. By using the tools mentioned above and working in tandem with your vendor, you will have effectively ensured the safest workplace possible.

When choosing a vendor for your packaging machinery, be sure that safety is of the utmost concern when it comes to their products. While there are multiple important issues that all companies must be concerned with, the safety of your employees and their environment must be the main focus of your packaging line.

Once you have completed the entire risk assessment process, you can rest assured that your packaging line will be running as safely as possible. As time goes on, it is a good idea to conduct additional risk assessments on a regular basis. This will prove especially helpful when adding new machinery or rearranging the physical footprint of your current packaging line.

Next, a pre-investment checklist will provide you with all the bullet points necessary to check off in the buying process of purchasing new packaging machinery. This tool will help you to identify various options for your machinery including dynamics such as size, speed, physical footprint, material specifications, ease of use, durability, additional options, and a host of other important considerations that will allow you to pinpoint the perfect machinery for your specific needs.

We suggest that you print out the checklist and review it. Take the time to really consider each section of the checklist and work with your packaging team to provide the correct answers. Be sure to include those who will be operating your equipment as well as those who will be servicing, supplying, and providing preventative maintenance.

This FREE checklist is designed to streamline your packaging machinery buying experience. With everything you need to consider in one place, this tool will ensure you get the right machinery for your particular applications!

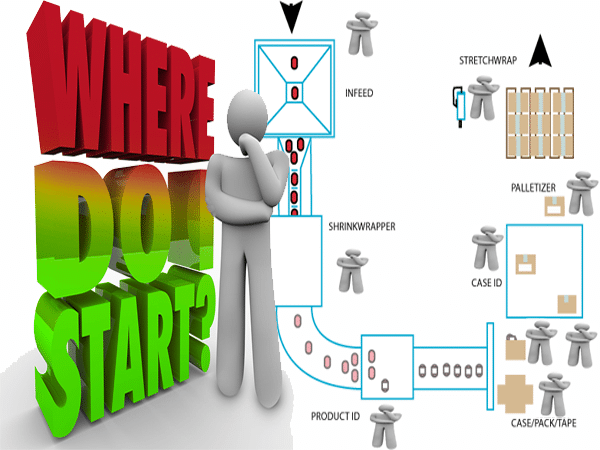

While there are many different types of packaging machinery, the most common include; shrink tunnels, pallet wrappers, case erectors, sealers, carded packaging machines, and form, fill and seal machines. There can be a lot of guesswork when it comes to finding the most reliable packaging machinery from various different brands. However, as a distributor, we offer multiple brands. Each of the brands we offer has its own strengths and weaknesses.

It goes without saying that researching a few different brand offerings for each piece of equipment you are planning to invest in is a very important step in this process. This will ensure that you choose the right machine for your company's budget, needs, capabilities, and product offerings.

Whether you decide to purchase brand new, used, or refurbished machinery, it is important to leverage the wisdom in this guide as a light in the dark on your journey to find the right solution for your packaging needs.

When considering which machines are the fastest, most reliable, or easiest to repair, we always start by looking at the customer rather than the machine.

We recommend service intervals that make sense for the customer. Sometimes that means annual maintenance. Other times it can mean semi-annual or quarterly maintenance. Keeping everything clean and running smoothly is ultimately how any machine can become the fastest or the most reliable.

Price is certainly a consideration for all customers, which is why the design of the machine is so important. Fewer parts often equal fewer things to break. Some newer machines don’t have the wear-and-tear that a pneumatic air cylinder might have, for example. Though, sometimes the benefits of the pneumatic air cylinder might justify the expense.

It is very important that you work hand-in-hand with a local packaging machinery professional who can help to guide you through the process of selecting the correct equipment for your needs without purchasing options you do not require.

It is also well advised to get at least a couple of different vendors to provide you with an analysis of your packaging line, machinery, products, materials, and the footprint of your physical packaging department.

By comparing the information from several different vendors, you will be able to define who has your best interest at heart. Choosing a vendor who takes your unique business needs into consideration rather than simply selling you machinery is an important aspect of choosing a machinery vendor.

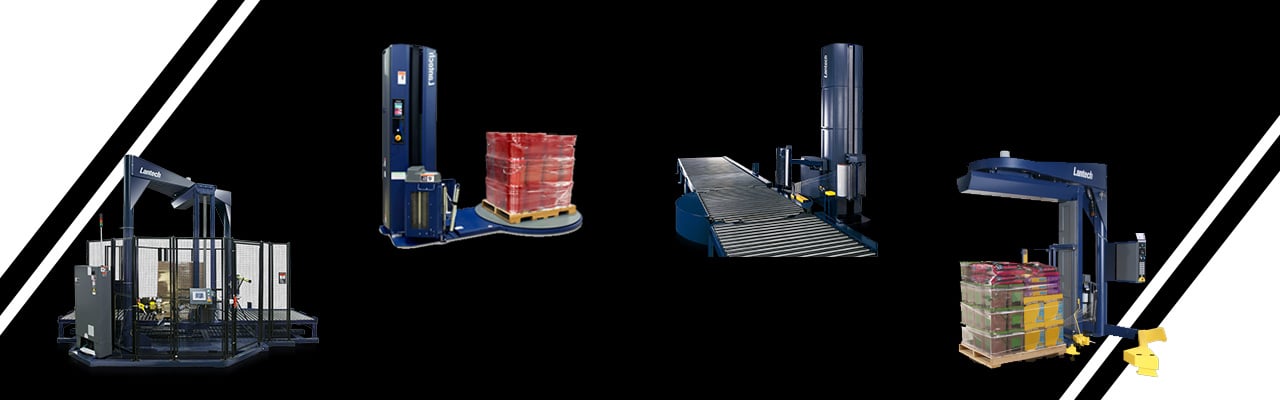

Pallet wrappers (or stretch wrappers) are ubiquitous in many packaging lines across the globe. Boasting significant cost savings for large operations over manual wrapping, using a pallet wrapper also maximizes the stretch capabilities of your stretch film. This ensures that you save both time and money.

A stretch wrapper will help you to ensure that you are in fact using the correct load containment for your wrapping process. When it comes to load containment, there are three important variables to consider:

There are several important variables to consider when implementing the proper load containment; primarily, length x width, and height. The larger the width x height, the easier the pallet is contained. With height, things are a bit more dynamic as the height of the pallet can increase or decrease load containment based upon the weight and perimeter. The ease of wrapping depends largely on how the pallet is packed.

First of all, you will need to decide if you want a semi-automatic or automatic stretch wrapping machine*. Space, capital, speed, capability, and needs are all important considerations for this decision!

A semi-automatic stretch wrapper is manually placed on a turntable and a piece of wrap is placed at the bottom of the pallet. from there, the machine will wrap the load according to your selections on the machine for load containment. The finished pallet is manually removed from the turntable and the next pallet is moved into place.

An automatic stretch wrapper takes a pallet and automatically puts it in the wrap zone where it is wrapped based upon the settings of the control system. When completed, the pallet moves down a conveyor to the end of your packaging line. As your fully wrapped pallet completes its journey, the next pallet is automatically being conveyed into the wrap zone.

*There is also another option called "simple automation" which is available from select vendors. This form of simplified automation allows for what is called "cut and clamp capabilities" which means that your machine operators are not required to get off their fork trucks to operate the control panel. This form of automation allows the equipment operator to drop the pallet onto the wrapper while the machine pushes it onto a roller conveyor.

In addition to the types of pallet wrapping machines mentioned above, there are different types of wrappers with different functionality. When trying to figure out which pallet wrapper would best suit your needs, you will want to research the following kinds of equipment: turntable wrapper, straddle wrapper, orbital wrapper, or ring straddle wrapper.

Each of these machines wraps pallets in a completely different way and each offers different variables to their load containment. Each type of machine is also meant for different applications. Reviewing the specs for each kind of machine and how the machinery is operated via video or live demonstration is highly recommended.

With this particular machine, the pallet is put on a turntable that spins while a wrap delivery system allocates the stretch wrap to the load being wrapped. The wrap delivery system generally begins at the bottom of the load and wraps up to the top and back to the bottom. Turntable wrappers are one of the most popular kinds of stretch wrapping machines and can be set up to work well with various types of applications.

With straddle stretch wrappers the load stays immobile while a wrap delivery system spins around the load being packaged. This kind of wrapper can wrap unstable, lightweight, and heavier loads and is capable of wrapping from low to high volumes.

An orbital wrapper (also known as a "ringer") wraps a pallet by going over and under the load being packaged as the load travels on a conveyor into the machine. Orbital wrappers are primarily used for packaging flattened or oddly shaped items such as pipes, rolled carpets, windows, etc.

Ring straddle wrappers are fast wrappers that are generally able to wrap 200 loads per hour. These machines are often found in the toiletry and beverage industries. They are extremely specialized devices and only make up a small portion of the stretch wrapping machines currently in use.

Straddle pallet wrappers allow for the load to stay still while the wrap delivery system spins around the pallet. It then pistons up and down while the film is evenly distributed around the pallet.

A fair amount of companies choose to utilize a stretch wrap dispenser and manual labor to wrap their pallets in lieu of a machine. And while many companies assume that they are saving money by using human labor versus purchasing a pallet wrapper, this is often not the case.

Depending on what you are paying your employees who manually wrap your pallets in addition to the number of employees you employ for this task, you could actually be losing money with a significantly higher TCO (or total cost of ownership).

Hand stretching is far slower and a human can only stretch the wrap at an average of 10% to 20%. Machine applied stretch wrap applies 200% to 300% to the stretch length consistently! Getting a quote for a pallet wrapper and looking at the TCO (total cost of ownership) of each option is an important comparison to make.

When it comes to stretch wrappers, Lantech is our go-to recommended source for all things stretch-wrapping machinery. Their reliability is second to none. They are the best in the industry for this particular type of equipment. They archive the records of all of their various models, which makes service calls an absolute breeze.

Their machines are famous for peak performance that goes on for decades (when coupled with proper usage and a quality preventative maintenance program). Lantech is capable of accessing extremely antiquated information from as long as 35 years ago.

They are able to provide documentation on everything that went into the equipment. Many competitors do not keep records in this fashion. This is but one of the multiple reasons they are the rock stars of pallet wrappers. Take their famous Q-300 model for example:

• Maximum versatility. Wraps large, tall, heavy, or fragile loads including doors, windows, and more!

• Choose from hundreds of options to customize your machine to meet your specific requirements.

• The utmost in safety. No pinch points or trip hazards. All motors and wires are completely enclosed.

• Intuitive controls require little or no training

Sealers are the machines in your packaging line that sit prior to the heat tunnel for shrink film applications. A conveyor sends your products down a line where they are placed inside of a shrink film bag. Next, the products pass under a heating element that descends from above, clamping down upon the bag and sealing it.

This takes place on both sides of your product producing contents that are now loosely sealed inside of a shrink film bag. Finally, the product moves into the heat tunnel where the film is heated, uniformly wrapping the shrink film around your product.

L-Bar and L-Sealers are the same devices. They are referred to in these names because the two seal arms look like an “L”. These are manual machines and they are available in a variety of sizes. This type of sealer requires an operator to load the product into the film and then pull or activate the frame to come down and seal the film. Some L sealers have an automated conveyor that the package sits on so when the seal bar comes up, the conveyor takes the package and introduces it to the shrink tunnel.

Some of the more common options available for these machines are:

This is basically a material consumption vs. flexibility decision. Depending on the unique requirements of your packaging line, one option may be a better choice than the other. Be sure to discuss each option with your packaging machinery vendor.

Allow for easy product changeovers

If you produce many SKU’s, need lots of flexibility, have lots of short runs, a side-sealer might be for you. If you have sustained runs of specific products, a lap sealer could save you a lot of money

No matter what you are choosing when making an equipment purchase, it's always best to have a knowledgeable Equipment Specialist on your side. Talk to a packaging professional to find the optimal equipment for your needs.

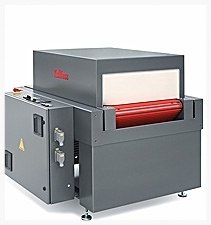

Shrink tunnels are a staple of countless packaging lines. When set up with the right temperature settings, they are packaging powerhouses and a sight to behold. They work by conveying products that have been placed inside of a shrink bag made from shrink film through a heated tunnel that causes the heat-sensitive film to shrink uniformly around the product inside.

Airflow from the machine prevents the products from getting too hot. If a product is particularly sensitive, special heat-sensing tapes are run through the machine to detect if the product is appropriate for packaging with a heat tunnel. If the tapes detect that a heat tunnel is not appropriate for packaging your product, other options can be suggested by your local packaging professionals.

There are various elements of a shrink tunnel that will affect the total purchase price of the machine. From the type and gauge of shrink film that you choose to run to the optional items you add to the machine, there are various things that can increase or decrease your total purchase price.

Below is an example that will give you a solid understanding of the total cost of a tunnel. Keep in mind, higher speeds and different options bring on different models and larger investments.

Compact and energy-saving shrink tunnel with patented ring nozzle heating system and especially effective regulation of the air volume. Equipped with a plastic mesh conveyor, for low maintenance and superior shrink results. This tunnel is ideally suitable for the shrinkage of small to medium size products with medium-capacity requirements.

Included Features:

Technical Specifications:

Additional Options:

While there are multiple OEMs producing shrink tunnels, we have found that the most reliable shrink tunnels are produced by Kallfass and Extreme. Both feature extremely high-quality parts and materials and are considered leaders of the pack when it comes to this particular type of packaging machinery.

Our team finds that the Kallfass Universa 500 and Servos machines rate the best overall.

As with any type of machinery, shrink tunnels and the materials run through them have common issues that can arise due to certain variables such as temperature. Here are a few of the most common problems that arise when the temperature is not optimized correctly.

● Flat Films Not Coming Off The Roll

○ When layers of flat film stick together, it’s called “blocking.” Usually, the film has been in excessive storage temperatures, which causes it to fuse together.

● Jagged Seals Or Incomplete Cut-Offs

○ Seals that look torn, incomplete, or jagged suggest that seal temperatures are too low. Try turning the heat up at 25°F increments until the film has a clean seal and sharp cut-off.

● Shrink Bags Take Too Long To Seal

○ Dwell time (how long it takes for the film to seal when the seal jaws are closed) varies. If dwell times are rising, it suggests that the temperature is too low, and vice versa.

● Strands Known As “Angel Hair” Start Showing Up Near The Seal

○ Strands that look like hair can appear between the sealed shrink film and the sealing mechanism. These are caused by the sealing wire or seal bar not being hot enough.

● Smoking Film Or Build Up

○ Smoking and polymer build-up on a pad demonstrate excessive heat. Worn pads can also create polymer buildup and smoking. It’s best to reduce excessive sealing head pressure and align them.

Of course, for every problem, there is a solution and for these issues above, honing in the correct temperature will largely fix all of them.

When storing your shrink film prior to use, make sure that you have a general idea of the best practices for the extremes of both summer and winter storage. During these times of the year, temperature restrictions are of utmost importance for these materials. If shrink film gets too hot, it can melt and stick to itself. If shrink film gets too cold, it can become brittle and crack.

Overall, shrink film is best stored in temperatures between 30 and 77 degrees Fahrenheit. Naturally, summer and winter are the seasons that require you to be most attentive to your storage environment.

The inside of your heat tunnel is an important dynamic to have locked in prior to packaging your product. The correct temperature for your product depends on which kind of substrate is being utilized. Furthermore, the appropriate heat for your product also depends on the gauge of your shrink film. More often than not, the most typical type of material run through a heat tunnel is 45 - 75 gauge PVC or polyolefin shrink film.

Let's run over a hypothetical situation that will allow you to better understand heat restrictions for your shrink films as they are passing through your heat tunnel. Say you are currently running a 75 gauge PVC shrink film:

An appropriate setting for PVC would be between 215 – 235 degrees Fahrenheit. Now, if you are going to use a polyolefin film with a gauge of 75, then an appropriate temperature for your heat tunnel would be about 255 – 275 degrees Fahrenheit. Keep in mind, these are just ballpark figures, and depending on the dynamics of your equipment, materials, and product, your actual settings may vary.

Carded packaging machines place the products they are packaging into a plastic shell that is backed either with a piece of blister board or another piece of plastic. The three types of carded packaging include blister packs, skin packs, and clamshells. Blister packs and skin packs feature plastic shells that are fitted with blister board backers while clamshells are made entirely out of plastic shells that close like their namesake shellfish.

Blister pack machines come in automatic and semi-automatic models. They feature rotating sections that hold the plastic portion of the blister pack in place. As the portion of the machine that rotates spins around, the empty plastic shells are either manually or automatically filled with the products to be placed inside. Next, the blister board backers are placed on the back of the plastic shell either by hand or by machine with an adhesive and the blister pack is completed.

While skin packs and blister packs share some similarities, the machine that creates the two items are very different from each other. Skin pack machines feature a platform where the blister board or backing substrate rests. The objects to be packaged are then placed upon the board. The machine then applies a heated layer of soft plastic that forms itself over the objects.

Vacuum sealing is occasionally implemented to ensure a tight fit. The substrate then bonds to the heat-seal coating on the cardboard.

There is a distinct difference between clamshells and blister packs. Clamshells are one-piece molded plastic with a hinge. They can be sealed with a variety of methods including buttons, pressed fit closures, staples, heat, RF, etc. The big factor is closing the lid automatically which can be done but this requires a lot more space.

There is a wide range of packaging machinery available beyond those discussed earlier in this guide. The few more common include case erectors, Form-Fill & Seal Machines, and Cobots.

Case erectors are machines that unfold or erect cardboard boxes to be filled with products. There are manual, semi-automatic, and automatic versions of this type of machine. On a manual machine, a human is required to unfold the box, fold, and or tape the flaps of the box into form by hand or by a taping machine, and the box is then sent down a conveyor or handed off to the next employee.

Semi-automatic erectors, complete the second and/or third steps automatically via a conveyor belt that moves the box through areas that force it into the correct shape. The erected box is then moved into a pile by conveyor or by hand. An automatic case erector uses mechanical elements such as a robotic arm to remove a box from a pile, unfold it and place it onto an automated conveyor belt. The box then travels the conveyor and it is filled with product and sealed either mechanically or by simple human interaction.

Next, the machine pulls each container further down the line, and funnels are used to slip contents such as food, liquids, or powders into the newly formed containers. These containers are then sealed shut with heating elements before they pass to the end of the machine and are conveyed into a cardboard box or similar container for transportation and shipping.

A collaborative robot (or CO-BOT) is a robot made to interact and coexist with human counterparts in a shared physical space.

A collaborative robot is a single or double robotic arm that can be trained to mimic motions or gestures. These robots can repeat the task over and over again. Some of these robots will improve upon the trained motions. After learning from the repetition of movements, they can learn to do better work.

These co-bots are also designed with safety measures. They have sensors that detect when a human counterpart enters a collaborative space. When this happens, the robot will slow down or come to a complete stop. When the human leaves the collaborative space, the robot continues to work.

Many companies use collaborative packaging robots to generate efficiencies in their operations. Collaborative packaging robots help companies get their products onto store shelves.

Collaborative packaging robots can be automated to increase their own productivity. They can adapt to constant changes in the consumer market. Co-pack robots are an excellent choice for many sorting and packaging responsibilities. They give their human counterparts the ability to focus on other work while they complete the more simple and repetitive work.

While it is technically possible to run a packaging department almost exclusively on human physical labor, most of the time it is neither a good or correct solution.

It is true that packaging machinery comes with a significant up-front financial cost, but the dividends that a quality packaging line with robust machinery can payout are worth their weight in gold. Below, we will take a look at the many benefits of using packaging machinery on your packaging line.

When it comes to producing a large number of quality products, a robust packaging line can make or break a company. This is especially true if you are producing a high volume of products in a short amount of time.

Sure, you can lean heavily on manual labor, packing tables, cardboard boxes, tape, and hand film. That being said, is it really a sound investment if your volume is more than your team can manage consistently?

Investing tens, hundreds, or in some cases millions, of dollars into packaging machinery can be daunting, but the money that this machinery can save for your company over the long term can make the investment worth it.

Furthermore, with financing and leasing options, getting your hands on the packaging equipment you need to take your production and your company to the next level is easier than it has ever been in the history of packaging.

The total cost of ownership is one of the most important dynamics to consider when you are weighing your options in regards to your packaging department. With the right packaging machinery, you will require a smaller labor force, therefore paying out significantly fewer wages.

Indeed, packaging machinery can come with a relatively large price tag, but when you take the total cost of ownership of a semi or fully automated packaging line and compare it to a warehouse full of manual laborers, the numbers begin to lean in the direction of machinery as the most viable option for success.

Taking the time to compare what you are paying for your labor force (not only in money and time but also in regards to hiring, firing, sick time, and vacation) to a primarily mechanized line may surprise you. Chances are, you may very well find that in reality, a machinery-driven packaging line with a few well-trained and dedicated operators is the better choice both financially and logistics-wise.

In other cases, you may find that right now is not the time to seek out the investment, but it's worth reviewing on a regular basis to make sure you are considering your overall costs and your future business goals and expectations.

Packaging machinery allows you to package more products per hour than physical labor. When the speed of getting your product to market is an important dynamic for your business, ensuring that you are running packaging machinery vs. physical labor is extremely important.

Human beings simply cannot package products as quickly or efficiently as an automated or semi-automated mechanical packaging line.

Packaging machinery does not take sick, personal, or vacation time. While downtime may occur due to mechanical failure or a broken part, these issues are easily remedied and are few and far between when you plan your downtime. When coupled with a regular preventative maintenance program, a mechanical packaging line can save you thousands of wasted dollars and hours per year.

As packaging machinery technology advances, we are going to see major leaps in speed, quality, and most importantly, automation. Packaging machinery is going to the robots and they are going to become the norm on the best packaging lines throughout the world for various reasons. The better prepared you are for this transition, the better off your company will be.

Production line automation allows companies to leverage ingenuity and efficiency without sacrificing craftsmanship or quality. With an automated production line, you never have to worry about employees getting sick, you can rest assured that production levels will remain high, and you can feel confident knowing that the end product will be made to a consistently higher standard.

Robotic packaging automation, in particular, mimics human movements to take the human being out of the process without sacrificing the yield of the process. This does not eliminate the need for good staff. Instead, it provides an opportunity to remove the repetitive, unskilled tasks that many humans find boring and unfulfilling yet are critical to meeting production needs.

In other words, robotic packaging automation provides an opportunity to maximize your staff while maintaining or increasing productivity. That’s a win/win situation for you, your employees, and your company.

In order to understand the cost of your packaging machinery, you must first understand your particular needs, the type of machine you require, and the additional options you want for your specific applications. It is important to also consider adding a contracted preventative maintenance plan or hiring a dedicated service technician to plan your downtime on your own terms.

With all of these factors in mind, the truth is that the cost of your packaging machinery is extremely case-sensitive. This is to say, the expense associated with your packaging line may vary greatly from your competitors. As each packaging line is unique with its own array of machinery, materials, energy requirements, operators, geographical location and etc., the cost associated with one line to the next is rarely identical.

In the section below, we will take a look at the various dynamics of a packaging line and the associated costs related to purchasing machinery, materials, and the other elements needed to properly run your equipment.

7 Questions

Material Usage

Price Per Package

Next, you’ll need to become more familiar with the math involved in your packaging materials. Let's take shrink film for example. Price per roll is an important dynamic to consider, however, your price per package is even more important. Understanding what each package costs, how to calculate it, and how you can save money will put you in a much better position to budget appropriately and maximize cost efficiency.

The math starts with a determination of your actual film usage and then leads into your actual cost per package:

Film length divided by film cut-off, minus the rewrap percentage, equals your film usage. Let’s say, for example, that your film length is the standard 4,375 feet per roll for 60-gauge center-folded film. Converted to inches, that is 52,500. Assume the film cut-off is 11 inches. If you divide this, it comes to roughly 4,772 packages per roll. Subtract the rewrap percentage of, say, 3%, and you get roughly 4,629 packages per roll of film.

This is much simpler math, as it’s just how much each roll costs you to purchase, divided by your film usage. So let’s say you are paying $128 per roll of film. Divide this number by 4,629 packages and then multiply by 1,000. You come up with a true package cost of $27.65 per thousand packages.

$128 per roll

4,629.57 packages per roll

128 ÷ 4,629.57 = .2765

.2765 × 1,000 = $27.65 per thousand packages

Use these calculations to formulate a solid expectation of your shrink wrap package price. Then consider the following tips for reducing that number.

When meeting with your sales rep, ask about special offers, rebates, and additional opportunities to reduce the cost of your purchase. Packaging machinery is a big investment and there may be various ways in which you can reduce the price of your purchase.

When buying a packaging machine you are likely going to get an offer from various sales reps. Unfortunately, many sales professionals will try to sell you a Cadillac when all you really need is a Toyota. When getting quotes from your chosen vendors be sure to ask about getting a base machine with no bells and whistles and only adding the options you actually need to successfully package your products.

It is also important to ask for quotes from several different manufacturers. Sometimes you can get a virtually identical offering from one company that is thousands of dollars less than their competitors despite any major difference between theirs and the other vendors' machinery.

Truth be told, sometimes you are simply paying extra for a brand name. When it comes to packaging equipment, buying a product because it is the most famous brand in the industry does not always translate to the best-packaged goods. You may actually get a better machine from a lesser-known brand that packages your product perfectly.

There are several dynamics for purchasing packaging machinery and their associated operation that is not a cookie-cutter solution for every business. There are some aspects of buying and running packaging machinery in which there are at least two options. One option may be right for your business and wrong for the next. These include:

A preventative maintenance plan is an additional cost to consider when buying packaging equipment, but it will save you thousands of dollars. When parts wear out, they can cause breakdowns that may result in extensive downtime and lead to highly costly repairs. If you are on top of regular maintenance, you will reduce the risk of more damage.

Damage may occur to other parts of your machinery when a worn-out part fails, let alone the risk of injury to your workforce. A regular preventative maintenance plan will greatly reduce downtime, keep your machinery running at peak performance and ensure quick repairs and service calls.

A different material formulation may reduce your cost on the machinery that runs it. IE: stretch wrappers and shrink machinery. What many companies often overlook is that there could be more than one kind of material that works for a particular product.

Bring in a rep from a couple of different vendors and have them run an analysis of your current packaging line. This will give both of you a large collection of valuable information about your particular packaging processes such as your current equipment, materials, and procedures. This information will allow you and your rep to find ways to improve upon your current processes before upgrading to new machinery.

It is important to identify some specifics about your product to be packaged before buying a piece of packaging machinery. For example, the materials that you will be running on your line are an important consideration when planning to buy new equipment.

If you are going to be buying shrink film machinery, you will want to look at all the different kinds of shrink film as well as the various gauges of films that are available. Choosing the wrong type, gauge, and size of the film can cost your business thousands of dollars over time.

When you are trying to figure out where you should buy your packaging machinery from, choosing to go direct to the manufacturer is a common choice. After all, who knows their machinery better than the people who are building said machines? You can be sure that the manufacturer knows their equipment inside and out. As such, they should be able to answer your most discerning questions.

That being said, the manufacturer will obviously be biased when answering questions like "which is the best brand of packaging machinery to buy" or "which manufacturer offers the best service"?

Now, just as there are various ups and downs when buying from an OEM, so it is with a distributor. From the cost of goods to customer service and quality in repair work, distributors have their strengths and weaknesses.

Depending on various factors including your geographical location, budget restraints, and other dynamics such as your production line's current infrastructure, a distributor may or may not be the best choice for your company.

There is an absolute myriad of considerations when choosing packaging equipment and materials are one of the most important items to consider. In addition to packaging machinery and materials, the environment and atmosphere also are important dynamics to ponder. Working with a distributor will allow you to review a plethora of options and they will be able to help you acquire the right information, advice, and products for your needs.

Extreme heat or cold must be offset by heating or cooling systems where extreme temperatures are the norm. Whether this means you live in a place where it is always one extreme or the next, or if you live in an area that can see both extremes throughout the year, ensuring that you have the proper heating and cooling systems in place is something to take seriously.

When it comes to the environment and packaging machinery, one thing is for sure. You do not want to run pneumatic machinery. Pneumatic technology is not only extremely outdated, but it is also bad for the environment as it uses an excessive amount of electricity.

Some machines have completely eliminated pneumatic components all together which results in huge cost savings as compressed air is one of the costliest utilities in a plant.

Since air cylinders wear, eliminating pneumatics will reduce purchasing replacements and the disposal of them as well. Some non-pneumatic machines also offer what is called “servo technology” which does not require you to add additional floor space and multiple conveyors to get the correct spacing between products.

Other machines also offer what is known as “lean technology” which eliminates film breaks. This means you don’t have to re-wrap loads and throw extra material away. Typically, machines with lean technology use less material with a special metered film delivery system.

In addition to negating or removing pneumatic technology from your packaging line, being sure to run environmentally friendly materials is also an important consideration.

While much of the metals that make up packaging machinery can be recycled, certain materials can not or simply are not recycled.

When choosing materials for your packaging it is important to consider using flexible packaging materials like shrink film and stretch film in place of high carbon footprint items such as glass, metal, and cardboard.

While also being considerably cheaper than these other materials, shrink film and stretch film are in fact completely recyclable. And with a significantly lower carbon footprint than the aforementioned alternatives, flexible packaging materials are in fact a far better choice for the environment.

Depending on the types of machinery you are running and how said equipment is laid out, it would be wise to create a plan for moving the right equipment at the right time. Depending on the size, electrical requirements, physical location on your line, and weight of your machinery, some planning ahead of time is an important dynamic of this process.

Reaching out to your packaging machinery and materials representative to help you formulate a plan based on the dynamics above will allow you to take a preemptive strike against unnecessary or repetitive actions during the transportation and installation of your machinery in its new location.

Depending on the flow of your packaging line, certain machinery should be installed first to ensure an efficient and timely installation. As for which machine you should move first, well, this is case sensitive for every business and should be decided by you and your technical service contact.

Buying new machinery is a big investment for many companies and oftentimes buyers are unsure or uneducated about the process. One very important consideration to think of right off the bat is, should you buy or lease the machinery you are planning to acquire?

The truth is neither option is one size fits all. Each has its own pros and cons and a different set of applications and line dynamics that would suggest one superior to the other. Ultimately your unique needs, layout, and budget will determine which option is best for your business.

There are however some considerations to ponder that will help you to decide which option is best for your packaging line and the unique applications in which it is involved. So with that in mind, let's review a few key elements of choosing to buy or lease your packaging machinery.

Capital investments should be made strategically and with the future in mind. Some of the things you'll want to consider when vetting leasing new packaging machinery over financing include how much you plan to use the machinery, how many machines you will be looking to acquire, potential investors in your business, and last but not least, your balance sheets.

![]()

Does it make more sense to buy your machinery outright or do you need to start out with leasing based on your budget? In evaluating/making a purchasing decision on equipment, people sometimes confuse the ability to justify the purchase with the ability to pay for the purchase. The ability to justify the purchase (ROI) is based on a business decision that the payback meets your requirements for investment.

If you want to have the best machinery on the market, you may have to do a little extra digging to find newer technologies that offer the best lease options for your business. That isn't to say that they won't be available, it just may take some extra legwork and research. Therefore, having a supplier that has experience in equipment leasing within the packaging industry is important.

When it comes to choosing a supplier for your packaging materials and machinery, it is important to do your homework and ask yourself a few questions. You should investigate at least three different suppliers and learn about several important dynamics from each of them.

It is a good idea to choose a packaging machinery supplier who is relatively close to your geographical location or can easily travel to you. This will have an impact on your business when there is a need for repairs or emergency service for your equipment. Pick a supplier who is in another country and you may find yourself dead in the water for days on end. Choosing a supplier with technicians who are local is always a smart idea. When it comes to your materials, you don't have to be as worried about the physical location as most supplies can be shipped timely.

It is important to choose a packaging machine supplier with experienced and certified technicians who are professionally trained to work on your packaging equipment. Without the proper certifications, you are taking a chance with your equipment. You could end up paying big when risking service with non-certified techs.

It may be tempting to source the cheapest packaging materials in an attempt to save money, but if you buy from a company with poor customer service, you may end up losing the anticipated savings anyway. Poor service often means lost dollars. Check out reviews of each vendor and if possible, reach out to current customers and ask about their vendor's customer service and if they would recommend buying from them.

There is an old saying in the packaging industry and that is "shrink film is shrink film". While there are some brands with flashy marketing and sales gimmicks with a premium price, chances are, there are several less costly alternatives that are of equal quality. If you are looking for comparisons, there are generally low-cost films that have lower clarity and higher-cost films that will shine more and have better clarity. Choosing an inexpensive film may cost you in shelf presence.

Snake oil and elevator pitches can blur the line between reality and illusion. At the end of the day, you will want to purchase from an honest supplier who carries multiple offerings at different price points and provides superior customer service.

![]()

Depending on how often your machinery is running, your downtime due to repair needs or emergency service will vary. As time is money, it is important to ask your machine supplier about lead times, parts availability, and preventative maintenance programs.

Ask each potential vendor what their average response times for emergency calls are. In most cases, it should not be more than 24-48 hours.

Different types of machinery require different types of materials and utilize different amounts of materials based on the make and model of equipment. For example, while you can save money upfront by purchasing a manual L-Bar Sealer, your cost of goods will likely be higher as a more expensive automatic sealer will generally use less material than the manual machine because the machine will generally be optimized to do so.

That being said, the quantity of product that you will be producing must also be taken into consideration. An automatic sealer won't be the right machine for a small business that is only running a couple of thousand items or less each week.

This is due to the fact that each model is designed to work with specific maximum and minimum capabilities and materials. Every machine is different. Your packaging line's unique needs must be taken into consideration when choosing the appropriate machine for your application. This can result in higher production costs if your choice of machinery cannot run thinner gauge shrink film. Using thinner gauges of shrink film can result in significant cost savings.

Buying packaging machinery is a major investment. The various dynamics of choosing machinery include; safety, budget, physical layout, electrical supply, materials, and a whole host of considerations that can make your head spin.

When moving forward with the buying process it is important to start by reviewing the appropriate KPIs with an emphasis on safety first. Next, you will want to be sure to complete the packaging machinery pre-investment checklist. After filling out the information in this valuable tool and getting your results back, you will want to move on to getting quotes from at least two or three vendors.

Getting an analysis of your packaging department and collecting data on your current machinery, manual labor, materials, physical footprint, electrical requirements, production levels, types of products and the other important dynamics of running a safe and productive packaging line is key.

Once you have been able to fully analyze every aspect of your packaging line, asking for quotes from each of the vendors you are giving an opportunity to quote will provide you with peace of mind that you are going get the best deal and receive the best of what each vendor has to offer.

In addition to requesting information and pricing on the packaging machinery you are looking to purchase, be sure to also acquire information about the cost of service, installation, any training available, supply, and repairs. Ideally, you should consider getting a quote for a long-term preventative maintenance plan as this type of program will ensure that your machinery is always running at peak performance and that downtime will be limited when it does occur.

Once you have chosen a vendor to buy from, meeting with your representative and reviewing the machinery offerings that they have will allow you to open a conversation about pricing. Here you can ask about special offers, rebates, additional options, leasing versus buying, and other related dynamics that will help you to get the best price and best plan implemented for your specific budgetary restraints and packaging line needs.

Finally, it would do you well to schedule quarterly, bi-annual or annual meetings for review with your chosen vendor's sales representative and one of their maintenance technicians.

This will allow you to review data from one meeting to the next and identify places where your machinery and materials could be improved upon to further reduce your cost of production, increase speed to market, create greater efficiency and produce a superior performance on your packaging lines KPIs.

Once you have purchased your new machinery and have worked with your chosen vendor to install the machinery, train your operators, and all else has been said and done, be sure to schedule your first review before your representative leaves your building.

If you heed the information in this guide, we assure you that you will make the best possible choice of packaging machinery for your packaging department. Furthermore, you will be able to ensure the purchase and implementation of the best materials for your products and may rest assured that you have done everything in your power to have the best possible packaging line for your business.

Should we not have produced answers to some of your questions or content that is crucial to your particular needs in regard to buying new machinery, contact us directly. Your voice can help others in your position in the future!

Our dedicated packaging professionals can and will answer any questions that have not been answered by this guide. In addition to what you have read here, we invite you to peruse our blog which is absolutely packed to the brim with useful information, free tools, and quality content that will make for a highly useful adjunct to this guide.

Last but not least, you will find a selection of free tools below that will help you on your journey to finding the best packaging machinery for your packaging line.

From all of us here at Industrial Packaging, we wish you well on your quest and again would implore you to contact us if you need anything else that you could not find in this guide.

An easy to use guide with a checklist of questions to review internally and externally prior to investing in new packaging machinery

This Calculator will provide you with 5 KEY ITEMS including what savings you could materialize with an investment, labor costs, and how long it will take to pay off!

This robust calculator takes into consideration your depreciation, labor costs, and more to provide you with an ultimate ROI report for your packaging machinery investment