The Most Reliable Packaging Machinery

Equipment | The Business of Packaging | Plant Performance | Investment | Shipping Protection | Food Packaging | Warehousing

Reliability is a key component when choosing any kind of machinery or mechanical device. When hundreds of thousands of products and a business’ entire distribution process is on the line, reliability becomes even more important.

Considering which machines or manufacturers are the best is a subjective process. What is best can mean one thing for a smaller business and something very different for a larger one. Best can also mean different things depending on your specific packaging needs, regardless of volume.

Deciding which machinery is the best for your unique business needs usually involves a compromise between physical space, finances, needs of the business, and suitability for the application.

In this post we share some of the packaging machines that have proven tops for our customers when it comes to these aspects. These machines also perform well in terms of reliability, ease of repair, speed, and customer service.

If you are preparing to invest in a packaging machine, get our free must-have checklist to help determine the best packaging machines for your facility.

The Most Reliable Shrink Sealers

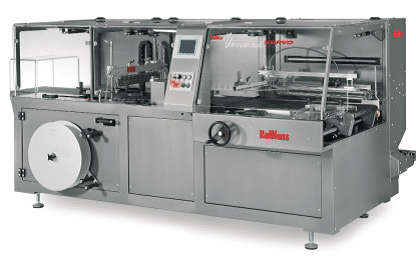

When it comes to which machines are the most reliable to meet shrink sealing needs, the overall construction and design of the machine is key. Our team finds that the Kallfass Universa 500 and Servos machines rate as the best overall.

Of course, utilizing our free, comprehensive pre-investment checklist will guide you to the right purchase for your own output, capital requirements, and ROI goals.

Kallfass has designed a machine that is able to eliminate a lot of the individual parts that older-style machines have used. Fewer moving parts equals fewer things to break. This translates into more productivity and fewer headaches for the client.

Older-style packaging machines have chains and sprockets that drive the mechanism. Power is not direct-drive to motor, which reduces efficiency and adds to the list of things that can break. New controls and motors are designed to use less electricity. Timing belts are reinforced to protect against wear and tear. Overall movements are more precise.

These improvements are not unlike the evolution we have seen in the automotive industry. Cars used to have less efficient engines, whereas now a single belt is standard, as are gas-powered motors. Over time, consumers will see less repair because of these innovations. The same is true with Kallfass.

The Extreme rotary is another example of an exceptional machine with a design that lends itself well to maintenance, which increases overall reliability.

For this machine, instead of working against the inertia of a moving roll carriage back and forth that has to stop, open, come back and repeat, all at speed, the new design has a head moving back and forth with top and bottom jaws that open and close. This is good for low-height packages like pizza boxes, individual frozen hamburgers, and the like. The high rate of speed is possible because the machine does not require constant opening and shifting of a big, high jaw.

The Most Reliable Stretch Wrappers

Stretch wrappers are necessary for shipping high volumes of pallets so it is no surprise that many packagers want a high rate of reliability for this particular need. Our service team finds that Lantech wrappers are consistently the best in this regard.

For Lantech, the key to reliability lies with their customer service. They keep extensive records of all of their machines, which is particularly helpful when service is needed. Not only do their machines last for decades with proper use and maintenance, they can pull up a bill of material from as long as 35 years ago with information on any particular machine. Lantech is able to provide information on everything that went into the machine. This is in stark contrast to some of their competitors, who don’t keep records past ten years. This is one of the reasons that they are our 'go-to' for customers looking for pallet wrappers.

Easiest to Repair

All machines have moving parts that experience wear and tear. The need for repair is inevitable. With Extreme, the design of the machines incorporates this understanding and makes for technology that is easy to service.

The owner of Extreme was a field service technician himself. When he started his own company making machines, he integrated what he learned from prior experience. For example, covers are easy to open. Once open, all parts of the machine are exposed for easy access. Everything is direct-drive, with the motor directly attached to the shaft.

Placing the motors in easy to reach spots, mounting the motors outside the frame, and making all of this easy to access leads to a machine designed for easy maintenance and repair.

Fastest

When it comes to which machines are the fastest, the answer is: it depends. An operation’s needs are different if the line is running 24/7 versus one shift a day, three times a day, versus three runs a week.

The type of process matters as well. Shrink-wrapping is a completely different animal when compared to stretch wrapping in terms of speed, client needs, etc.

When a client is asking for a machine to make their line faster, we start with a line audit of the overall operation. We consider the budget, and the goals of the company. Sometimes the issue isn’t about the speed of a specific machine, but about examining the whole process.

One customer found that changeover time between items took 4 hours. We created a longer line so that while they were running one item, they could send materials up for the next job, and only had to switch the labels out. This increased the speed of the line overall, while the speed of specific machines did not necessarily change.

The Big Picture

When considering which machines are the fastest, most reliable, or easiest to repair, we always start by looking at the customer rather than the machine.

We recommend service intervals that make sense for the customer. Sometimes that means annual maintenance checks. Other times it can mean semi-annual or quarterly checks. Keeping everything clean and running smoothly is ultimately how any machine can become the fastest or the most reliable.

Price is certainly a consideration for all customers, which is why the design of the machine is so important. Fewer parts often equals fewer things to break. Some newer machines don’t have the wear-and-tear that a pneumatic air cylinder might have, for example. Though, sometimes the benefits of the pneumatic air cylinder might justify the expense.

Conclusion

Overall, we feel our best line is with the Kallfass shrink wrappers. We know that is often an expensive option, though, and that a lot of small businesses can't afford that kind of investment.

We always consider the big picture to determine the best recommendations for every client. Looking at that big picture, building relationships, and keeping the customer’s needs front-of-mind tend to be the most effective approaches when considering the best in packaging machinery options.

We also offer a free tool to help you determine the best purchase for your facilities’ needs. Our checklist will help you:

- Compare the sizes of packaging machines vs. the available space in your facility

- Identify the ability of your current workforce to handle potential new challenges

- Figure out the speed your production will need to reach in order to meet your goals and more!

About David Roberge

I am grateful to be part of the outstanding Industrial Packaging team. I am able to hang out with some of the most knowledgeable folks in the packaging industry. I feel even luckier that I am able to share that knowledge with you. I love learning, hiking, and growing people and teams both personally and professionally, and helping companies grow better.